Maritime navigation has gone from a sailor finding his way with a sextant and the stars to technology so advanced that artificial intelligence can chart a precise course without a human being on board a vessel.

Companies around the world have developed a variety of smart solutions and services in recent years that support seafarers and marine vessels in achieving safer, more accurate and efficient voyages. Industry-wide, there’s a focus on autonomous control, reducing human error, increasing connectivity, improving route planning and overall digitalization.

Industry leaders shared some of their latest innovations, including the use of artificial intelligence (AI), with Pacific Maritime Magazine.

ABB

The marine division of Switzerland-based global technology company ABB is focused on automation for the future of the marine industry.

Automating certain onboard tasks by interfacing with traditional sensors and charts and camera technology, combined with AI-powered computer vision helps future-proof ships, explained Ola Hjukse, ABB Marine & Ports’ products and technology manager for automation & control.

ABB’s solution is the Ability Marine Pilot, which provides a single point of control for maneuvering the vessel at all speeds, Hjukse explained. This contrasts with the traditional approach of having several segregated systems handling the maneuvering of the vessel in different stages.

“Having one control system in charge of maneuvering enables making the vessels ready for upgrading to more automated functionalities just by software,” Hjukse said. “Autonomous technologies (offset) human weaknesses with the strengths of automation – repeatability, consistency, etc. This can have a drastic impact on the safety of ship operations to mitigate human error and enable human crew to use their strengths – creativity, problem solving, handling of complex uncertainties and human judgment – when needed.”

This calls for automating or partially automating some of the complex tasks manually performed, Hjukse noted. Examples include the lookout, who uses his/her eyes to understand the environment around the vessel, or the officer of the watch, who fuses data sources from observations and other sensors to create a comprehensive picture of the situation.

Although automation is there to serve people, not the other way around, ABB Marine & Ports Global Program Manager Kalevi Tervo added.

“We as humans have strengths that machines cannot compete with,” Tervo commented. “On the other hand, automation has strengths which can nicely complement the human weaknesses. Therefore, the industry needs to focus on developing solutions which optimally utilize the strengths of human and automation.”

The industry is trending toward smart solutions as they are viewed as a key to optimizing and greening operations, Tervo pointed out.

The latest public announcements on this topic for ABB Marine have been the remote control (2021) and autonomous control (2022) tests in the autonomous tug project in Singapore. The solutions were both recognized for their focus on safety in the design and development process.

“Going forward, we see more commercial use of these capabilities in several ship segments enabling (operators) to achieve safer and more efficient operations,” Hjukse said.

Last year ABB, partnering with Keppel Offshore & Marine, remotely controlled the tugboat Maju 510 in a Singapore harbor using a joystick.

In a follow-up trial earlier this year, ABB hit another milestone with the tug, Hjukse said. Digital technologies from ABB enabled a “breakthrough performance” of the Maju 510 in trials at Raffles Reserved Anchorage, off Singapore Island, in March. The tug demonstrated automated situational awareness, collision avoidance and maneuvering control provided by ABB Ability Marine Pilot Vision and Marine Pilot Control.

In August, following the trials, the tug became the first vessel in the world to receive Autonomous and Remote-Control Navigation Notation from the American Bureau of Shipping classification society and first Singapore-flagged vessel to receive the Smart (Autonomous) Notation from the Maritime and Port Authority of Singapore.

ABB is also currently in the process of delivering the Marine Pilot platform for an autonomous-enabled Crowley electrical tug in the U.S.

ADVANCED NAVIGATION

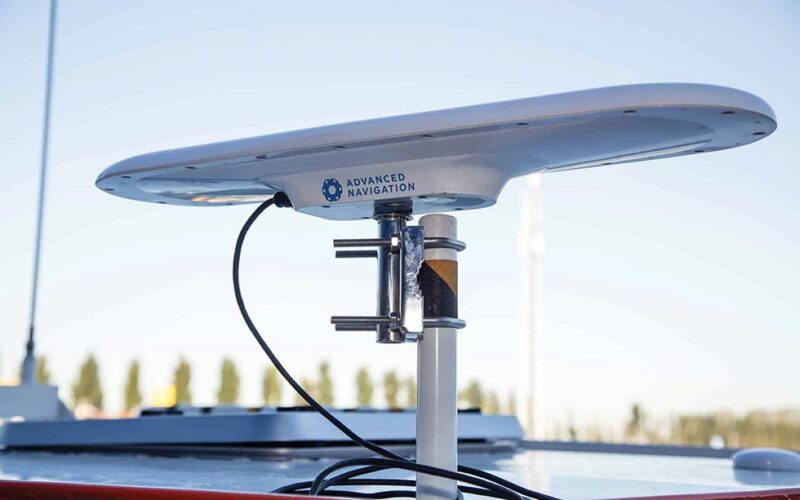

Australia-based Advanced Navigation, which focuses on AI-powered navigation systems and robotics technologies, recently released its latest satellite compass, an all-in-one GNSS/INS navigation and heading solution.

It provides accurate dual-antenna GPS-based heading that is not subject to magnetic interference and can maintain accurate heading during Global Navigation Satellite System (GNSS) outages of up to 20 minutes. The “plug-and-play” solution for marine vessels features high-accuracy positioning, heading and time.

The latest compass highlights an overall trend. Peter Baker, senior subsea product manager at Advanced Navigation, noted a greater need for Inertial Navigation Systems (INS) in the maritime industry.

Global navigation satellite system vendors are trending in the direction of moving away from GNSS-only solutions for position information, and rapidly integrating INS into their products. This is driven by several reasons, he said.

Firstly, an INS can provide updates at a higher rate than a GNSS.

“An INS uses accelerometers and gyroscopes as the motion and rotation sensors to calculate the location, orientation and velocity of a moving object,” Baker explained. “This allows it to output data much faster and provide orientation data, roll pitch and heading, which the traditional GNSS system is incapable of achieving.”

Secondly, an INS can operate in GNSS-denied environments, such as underground and tunnels, areas with tall obstacles, ravines, canyons and valleys.

“GNSS is suitable until the equipment can no longer collect a clear view of the sky and decent satellite coverage to provide position,” Baker said. “As an INS applies the principle of dead-reckoning and data fusion to estimate position, it makes for a reliable technology when GNSS positioning information is unavailable.”

The market for INS equipment is broadening in the maritime commercial and civilian sectors, Baker pointed out.

“By fusing INS and GNSS data, companies can largely improve their position accuracy. This is well suited for marine users who are operating in complex marine environments where navigational accuracy is paramount or where traditional GNSS may be degraded, such as port environments where overhead cranes or bridges can block satellites,” he added.

Baker also mentioned another Advanced Navigation product that responds to a different maritime trend.

Seeking an overall reduction in costs and fuel time while shrinking their carbon footprint, the subsea industry is rapidly moving toward remote offshore operation, he pointed out. As a result, maritime companies are opting for smaller-scale remotely operated vehicles (ROV) whose positions are tracked by Ultra-Short Baseline (USBL) systems.

“Bulky USBL systems can lead to extensive and expensive modifications to ROVs to fit, which can potentially impact the ROV’s operation, buoyancy and manoeuvrability, adding further complexity to solve,” Baker said. “This renders the size of the USBL critical for small-scale ROVs, as it needs to be small enough for seamless installation and without compromises in its operational capabilities.”

One such product that fulfils this requirement is Advanced Navigation’s next-generation USBL, Subsonus. it provides high-accuracy position, velocity and heading at distances of up to 1,000 meters and is small enough fit in the palm of a hand.

“The system also features an industry-leading calibrated hydrophone array combined with an internal tightly coupled INS, all packed into a miniature titanium enclosure that can be installed onto ROVs easily,” Baker said.

Subsonus’ unique dual USBL transducer architecture provides several benefits, he added. First, system accuracy and error correction are enhanced by performing USBL calculations at both the vehicle and the surface vessel. Advanced Navigation’s AI-enhanced data fusion algorithm can look at the system as a whole and to utilise data from each transducer to account for uncertainty when calculating position of the tracked ROV.

Subsonus also provides full INS capability to the ROV for position plus roll, pitch and yaw. In addition to position data, the INS functionality provides acoustically transferred heading from the surface vessel. This provides ROV pilots with accurate vehicle orientation information.

Subsonus also can be paired with a GNSS compass for even higher accuracy and heading data.

NAVTOR AS

NAVTOR, headquartered in Norway with locations in the U.S., offers innovative e-navigation and vessel performance solutions.

All the company’s products and services are a part of the NAVTOR ecosystem, an integrated, single user-friendly platform where databases and permits are automatically distributed and updated through its cyber secure NavBox.

The NavStation takes the navigator through all the stages for a proper passage plan – starting from creating the route – and further to a full passage plan that takes charts, publications, environmental regulations and environmental conditions (including weather and tidal information) into account, NAVTOR Nautical Advisor Johan Stensaker explained.

“We try to gather various layers of information easily accessible for the user,” Stensaker said.

NAVTOR recently launched what it believes to be a “transformational tool” for navigators, with the introduction of an advanced auto-routing module to its NavStation digital chart table.

The new auto routing module can prepare a smart route suggestion between any two positions in seconds. And not just from port to port, but from “point to point,” including from your own ship position to any position, or a selected position on the map to any position.

The customizable (to the needs of each vessel and voyage) and detailed routes are instantly available and can be seamlessly updated, compared and shared.

Out on the water, NavStation can make a significant difference for maritime vessels.

Auto routing allows for a quick outline of new routes for further passage planning, Stensaker said. It provides information on environmental regulations along the route, which helps to avoid discharge in specific areas, Stensaker gave as an example. The initial calculations also indicate where more detailed calculations, such as speed reductions or other actions, are needed to achieve safe clearance.

In what NAVTOR calls a “new dawn” for fleet management, NavFleet offers enhanced efficiency, cost control and performance.

NavFleet can improve vessel performance, enable better decision-making, enhance situational awareness, simplify workflows and save time, according to NavFleet Chief Business Development Officer Arild Risholm Sæther.

“The standard configuration includes tools to track vessels, overlay data layers and see weather forecasts. If a vessel is equipped with NavBox, NavStation and Passage Planner from NAVTOR, you will also have more advanced monitoring functionalities,” Sæther said.

NavFleet can also be extended with noon reporting, emission and compliance tools and performance tools.

“The performance tools give insightful analytics to help improve vessel and fleet efficiency, while also ensuring environmental compliance,” Sæther noted.

Earlier this year, the company introduced carbon intensity indicator (CII) tools. The new features in NavFleet support proactive planning and monitoring of CII in line with required targets set by the International Maritime Organization.

“We have functionalities within our voyage planning tools to see predicted CII on a voyage level with different speed profiles,” Sæther explained.

About 300 vessels are currently using NavFleet services, according to NAVTOR.

“We’ve seen a request for higher frequency and accuracy of data. Our clients would like data to be auto populated from sensors directly into reporting forms in order to simplify workflows,” Sæther said.

Insight (VFI) shared several updates in 2021 and 2022, including enhanced vessel tracking and route planning. Image: Voyager Worldwide.

VOYAGER WORLDWIDE

Headquartered in Singapore with offices around the globe, Voyager Worldwide provides maritime technology solutions to more than 1,000 shipping companies.

Voyager Fleet Insight (VFI) is part of the company’s ecosystem of navigation solutions spanning shoreside and shipborne applications designed to drive safety and improve voyage efficiency, Voyager Director of Product Management and Marketing Hayley Van Leeuwen said.

VFI shared several updates in 2021 and 2022, including enhanced vessel tracking and route planning. The system has undergone continuous upgrades to help ship managers better monitor voyage status, with online fleet tracking and operations support, Van Leeuwen explained.

“The most recent enhancements are designed to simplify and streamline core ship management tasks, including improved voyage tracking features and new alerts, the ability to manage office technical libraries and a refreshed map interface,” she said.

VFI’s vessel tracking module provides users with a detailed view of vessel routing, including departure and arrival ports, berths and times, distance travelled and stationary periods.

Van Leeuwen said Voyager Worldwide’s direction as a company reflects the “megatrend” within the maritime industry: The need to embrace digitalization as a means to optimize voyage performance and reduce the costs and environmental impact caused by port delays and supply-chain congestion.

Port congestion has worsened since the pandemic, she noted, and supply chains struggled under the weight of shipping demand as a combination of logistical delays and extreme weather saw ports overwhelmed and ships forced to wait at anchor.

“This has made it harder than ever to predict accurate port arrival and increased average wait times outside ports, delaying shipments and driving up carbon emissions,” Van Leeuwen said. “Stakeholders across the supply chain acknowledge the need to optimize ocean voyages to achieve just-in-time arrival, making significant cost-saving efficiencies and a contribution to building a sustainable shipping and ports industry, including the (International Maritime Organization’s) goal of reversing the shipping emissions trend and getting to net-zero emissions by 2100.”

Central to this change is a shift from shipping’s paper-based operating heritage toward a digital future, Van Leeuwen said. To reflect the changes taking place in the industry, Voyager Worldwide has partnered with the Maritime and Port Authority of Singapore (MPA) to promote joint innovations that support voyage optimization and just-in-time port arrivals.

RAYMARINE

Headquartered in the United Kingdom, Raymarine provides high performance marine electronics to boaters around the world.

The company introduced its Cyclone open-array radar in February. It’s a high powered, solid-state marine radar system with all-weather performance that gives mariners the confidence to tackle even the harshest conditions.

It’s a great solution for small commercial vessels, Raymarine Americas spokesman James McGowan said.

Cyclone uses CHIRP pulse compression technology, which provides excellent target separation and long-range resolution, he explained. It delivers a detailed picture with accurate shoreline depiction and great discrimination between close-together contacts

It also has a Doppler mode that can be used to colorize in-motion radar targets.

“Inbound targets are red, outbound green, which helps the operator manage traffic more effectively,” McGowan said.

Cyclone also has standard ARPA capability with the ability to track up to 50 targets simultaneously.

The radar meets IEC 62388 standards for commercial shipboard radar, and boasts a best-in-class 100-knot wind speed rating making it ideal for fast vessels, and those venturing out in all weather conditions, McGowan pointed out.

Cyclone is offered with a 3-foot, 4-foot or 6-foot antenna and a choice of 55 or 110-watts of transmit power. It has a maximum range of 96 miles.

In February, Raymarine unveiled YachtSense Link, an onboard marine mobile 4G router.

For coastal and harbor craft that are normally in-range of the major mobile carriers’ networks, this device can manage internet connectivity, McGowan explained.

YachtSense Link creates an onboard wired and wireless network for all types of devices needing internet access. It remembers Wi-Fi hotspots and can connect to them automatically when the vessel is at the dock, sending all network traffic through the shoreside hotspot.

When the vessel is out of Wi-Fi range on the shore, YachtSense Link can shift all traffic to the 4G mobile network. This happens automatically, and seamlessly to users onboard the boat connected to the network, McGowan said.

“The beauty of it is there is no need to shift individual devices from one network to another,” he noted. “They can remain connected to the onboard network generated by YachtSense Link and receive uninterrupted coverage.”

ALPHATRON MARINE

Alphatron Marine, a Netherlands-based subsidiary of Japan Radio Company, is a navigation systems supplier that works on innovative solutions that match with today’s technology and capabilities.

Jun Nakazawa, general manager of JRC Americas, shared news about the company’s recently released JRC solid-state X-band radar sensor.

In October 2021 at Europort, the international maritime exhibition, JRC/Alphatron Marine presented the solid-state radar technology, which offers high performance and low maintenance costs. The solid-state X-band radar sensor was approved by regulatory agencies in early 2022 and delivery is expected by the first quarter of 2023.

The model features a 600W solid state scanner antenna to be a part of JMR-9200/7200 series radars. It offers a 6-foot and 9-foot up-mast antenna, the same pedestal casing as NKE-1125, 25kW magnetron type.

It also fully complies with the latest International Maritime Organization performance standards.

In the technical report about the development of X-Band shipborne solid-state radars, officials note that there’s a need for this type of system.

“Maintenance-free radars are strongly demanded by customers, because radars are more and more frequently relied upon for ensuring safe navigation of vessels, consequently making the maintenance costs burden to replace magnetrons with limited life,” the report reads. “On the other hand, radar frequency band is demanded to be narrowed because of the present congestion of radio frequency resources.”

ORCA AI

Based in Israel, and with offices in England and Greece, Orca AI focuses on advancing the maritime industry by providing intelligent navigation solutions. The company’s AI-empowered technology helps the captain and crew get an accurate view of the environment in real time and make fast and safe decisions.

In February, Orca’s AI-powered collision avoidance and navigation safety platform received product design assessment certification from the American Bureau of Shipping.

The automated situational awareness system combines AI and data generated from multiple sources, including computer vision sensors and thermal and low-light, high-resolution cameras.

A cargo ship using Orca AI’s safety navigation system reportedly performed the world’s first autonomous navigation voyage of a container ship in congested water off the coast of Japan in February.

Orca AI provided the ship with a 360-degree observation system using 18 cameras and integration of the ship’s sensors.

FURUNO

Furuno Electric Co. Ltd., a Japan-headquartered company with offices in the U.S., recently released a significant software update for the RD50, an LCD remote display unit that displays a variety of data from onboard sensors.

In April, the Furuno RD50 Remote Data Display received an upgrade with software version 1.16, which introduced the new 3-axis speed indication when connected to a satellite compass.

“Critical for towboats, ferries and other commercial vessels, three-axis speed indication simultaneously displays important speed information for three different points of reference: longitudinal speed (ahead-astern), transverse speed port-starboard at the stern and transverse speed port-starboard from a user-determined reference point,” officials shared in a news release.

Onboard sensors deliver a wide variety of data to the RD50’s 8.4-inch color LCD screen. There are multiple display modes to choose from, including digital, analog and graphic display configurations. It can display large, easy-to-read numbers or even four-way splits, and provides adjustable background colors for use in the dark of night or direct sunlight.

The RD50 also comes with multipurpose mounting options so it can be installed wherever needed: in a bridge deck console or an overhead console, on a desk or countertop, or even outside with the use of an optional waterproof pod. Up to 10 displays can be connected with a daisy chain cable.

“The new three-axis speed indication is a highly desirable feature on professional bridges that activates when connected to a satellite compass such as the SC70 or SC130,” according to the news release. “These versatile satellite compasses prove their value by increasing the accuracy of other devices, such as radar, ARPA, scanning sonar, current indicator, chart plotter, ECDIS and autopilots. They provide a highly accurate heading input utilizing the latest GNSS.”