Container ships, tankers, cruisers – the majority of seagoing vessels with an engine power of at least 20,000 kW are equipped with a three-stage air-cooled starting-air compressor these days.

The powerful technology reduces heat and allows for enormous cost savings. Sauer Compressors discovered the potential of three-stage air-cooled compressors for the shipping industry early on and has been a pioneer in developing these compressors for almost 50 years.

In 1975, when the Railship I first entered service on the Travemünde, Germany to Hanko, Finland route, it had been the world’s largest railway ferry. While its length of about 180 meters (590.5 feet) was quite remarkable at that time, it would almost look like a toy ship next to today’s ULVCs (Ultra Large Container Vessels). On board the ferry were Sauer’s three-stage air-cooled compressors, which was a first at that time.

Almost five decades have passed since then, during which Sauer Compressors delivered over 30,000 of these starting-air compressors. Despite many developments, the basic operating principle of the technology has not changed a lot.

“Today, about 80% of large container ships are equipped with three-stage air-cooled compressors, making them industry standard,” said Stephan Behrens, Global Head of Business Development Commercial Shipping at Sauer Compressors.

The comprehensive establishment of the three-stage air-cooled starting-air compressors took some time, however. Many shipping companies and shipyards stuck with the previously common two-stage water-cooled compressors, instead of switching to generally advantageous air-cooled machines.

Large Ships, Large Engines, Large Fill-Up Capacity

To start a ship’s engine, compressors fill 30 bar compressed air into air receivers whose volume is determined by the engine size. As required by classification societies, the amount of compressed air must be sufficient for a certain amount of engine starts. The increase of the international trading volume starting in the 1950s led to bigger ships and engines and therefore a higher demand for compressed air.

Two-stage water-cooled compressors were the most common solution for starting the ever larger diesel engines. Due to their comparably low fill-up capacity, the two-stage air-cooled compressors that were commonly used for smaller ships were not a viable alternative.

But Sauer Compressors was eager to enable the use of air-cooled compressors for large ships and engines as well. In the early 1970s, the company came up with the idea of adapting three-stage air-cooled compressors as an established solution from the industrial sector to commercial shipping. However, despite their successful application on the Railship I and several other ships, the three-stage air-cooled compressors could not establish themselves as industry standard.

“The building of large cargo ships was relocated to Asia and the local shipyards simply took over the established design standards,” Behrens explained.

Only with the new millennium were multi-stage air-cooled compressors finally put on the standard makers list of the Asian shipyards. Sauer Compressors was able to convince ship owners and builders not only with references but also with specific demonstrations. For this purpose, a three-stage air-cooled compressor was installed in a TEU container and presented worldwide.

“The decision makers were able to experience the benefits of the technology themselves, for example how the compressor works reliably at high ambient temperatures, with low-vibration, and that no condensate is produced in the crank drive since the compressor always adjusts to the ambient temperature,” Behrens recounted.

Reduced Temperature Thanks to 3 Compression Stages

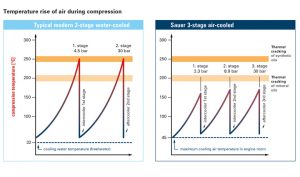

Three-stage air-cooled compressors are bigger and therefore have a significantly higher fill-up capacity than two-stage air-cooled machines. The total heat to be dissipated is divided between three stages instead of two and the heat-dissipating surface area increases while the heat-generating volume remains the same.

They are also superior to water-cooled machines for multiple reasons. By dividing the total compression ratio by three, the compression temperatures in the cylinders and valves of 3-stage air-cooled compressors are up to 30% lower than those of two-stage water cooled compressors, which may well reach 250°C (482°F).

Due to these comparably low temperatures, there is no thermal cracking of standard mineral oils. The maintenance intervals of valves therefore increase to 4,000 hours in contrast to 2,000 hours for water-cooled compressors. Instead of expensive synthetic oils, conventional SAE-30 mineral oils such as those used in two-stroke marine diesel engines for circulating lubrication of the crank drive may be used to lubricate the compressors. Thus, no expensive synthetic oil is required. With ongoing operation, the long-term maintenance costs are up to 30% lower for air-cooled than for water-cooled compressors.

Quick Amortization

Cooling the starting-air compressor with room air makes a cooling water circuit obsolete. This can save installation costs of up to $ 7,500, Behrens said, plus it avoids leakages and troublesome condensate in the crank drive that occurs when travelling through different climate zones. Other benefits include reduced space requirements in the engine room, higher reliability, and minimum operating effort of the self-regulating air cooling. There’s no need to modify the fan output of the engine room ventilation since the waste heat of the compressor is negligible compared to the heat of the ship’s engine.

As the new generation of three-stage air-cooled compressors is extremely powerful, the number of compressors required to reach the fill-up capacity that’s needed for large ships is now lower than it was years ago.

“A 24,000 TEU ship usually only needs three to four starting-air compressors, out of which one only serves as a reserve,” Behrens explained.

New Compressors

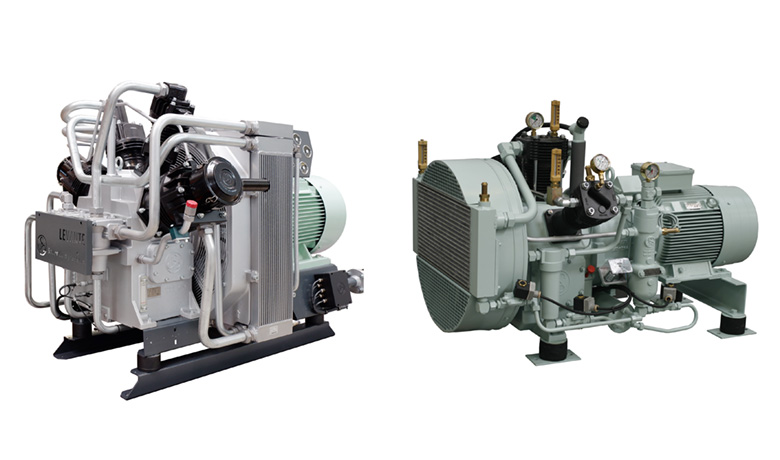

Sauer Compressors is a technology leader in the field of three-stage air-cooled compressors and covers the whole range of market requirements with two series. The models of the new SAUER Levante series are particularly powerful.

“By introducing our Levante series, we have responded to the ongoing trend towards larger ships and are the only manufacturer worldwide to have recently presented a completely new development,” Behrens said.

The compressor, exclusively developed for commercial shipping, is available in three different types, with capacities between 275 and 460 m³/h at a final pressure of up to 30 bar.g. With their compact and space-saving design, the compressors fit into most engine rooms.

A unique selling point of the design is the use of block coolers in all three stages. By installing the newly developed SAUER CubeCooler between engine and compressor, the air flow is optimized and moving components are shielded. Before their market launch, the Levante compressors were tested for more than 20,000 operating hours on Sauer Compressors’ test stands as well as on ships operated by partner shipping companies.

Additionally, the SAUER Passat 3-stage air-cooled compressors are among Sauer’s best sellers. There are five different types of SAUER Passat compressors available, with capacities between 63 and 175 m³/h at a final pressure of up to 30 bar.g.

William Koester is the head of marketing for Sauer Compressors.

Sauer Compressors is a medium-sized German group of companies with 14 international subsidiaries. The company has a more than 135-year history and over 85 years of experience in compressed air and gas technology. Currently, its focus is on the development, manufacture and sale of oil-lubricated and oil-free medium- and high-pressure compressors for applications in commercial shipping, industry, petrol industry and the defense sector. More information at: www.sauercompressors.com