West Coast shipyards have been busy recently with everything from minor maintenance to major re-power projects. Some yards are also working on enhancing onshore operations and increasing their equipment’s capabilities.

Pacific Maritime Magazine reached out to yards up and down the coast to find out the latest news on yard improvement and other projects. Some updates that stand out include managing double-duty operations; notable work with dual-fuel technology; challenging Tier 4 re-power jobs; the restoration of a historic wooden steamship, and installation of larger lifts and expanded drydocks.

Seaspan Shipyards

Seaspan, based in North Vancouver, British Columbia, has been busy, including several large commercial repair projects in 2022 at the Seaspan Vancouver Drydock, company spokesperson Ali Hounsell said via email.

Over a few months, four separate cruise ships came in for service, Hounsell noted, with two being worked on simultaneously, a first for the drydock. One was the Hurtigruten Expedition’s m/s Roald Amundsen, which received maintenance work, including minor steel modifications and a new coat of paint for the underwater hull. The luxury Seven Seas Mariner came in July, followed by the National Geographic Resolution and the Regatta in August.

“Having two large cruise ship projects on the go at the same time was challenging in that it was the first time we had two cruise ships of this size docked at the same time, with each bringing with them several hundred staff and crew,” Hounsell said. “We altered our drydock operations to run 24/7 during the time these vessels were in, which allowed the Seaspan team to work non-stop for the two-week long period.”

On average, Seaspan turns around about one new project per week, she added.

At Victoria Shipyards, the Seaspan team was busy all year with a mix of work ranging from long-term government programs to commercial repair and maintenance.

On the commercial side, the most significant project at the shipyard in 2022 was the conversion of TOTE Maritime Alaska’s ORCA class vessel Midnight Sun to run on liquefied natural gas dual-fuel technology, Hounsell remarked.

“Our team of nearly 600 experts across multiple trades at Victoria Shipyards carried out the final transition of the vessel to support dual-fuel operation, which involved installing five kilometers (3.1 miles) of piping to modify systems throughout the vessel,” she explained.

The team also installed new structural decks to support the two new LNG tanks behind the bridge. Additional modifications were made to the electrical systems and structural insulation was renewed to comply with regulations.

So far in 2023, Seaspan has completed the same LNG conversion work on the Midnight Sun’s sister ship, the North Star.

“With a global interest in combatting climate change, we are also confident that Seaspan’s new LNG conversion capabilities will become of interest to operators on the West Coast, as more organizations look to alternative fuel sources,” Hounsell said. “The return of cruise ships in British Columbia also helps to further bolster our optimism for the return of our regular cadence of repair and maintenance work in that sector.”

Seaspan yards are also working on improvements to enhance operations, including at Vancouver Drydock where, as of the time of publication, they’re awaiting a decision from the Port of Vancouver on Seaspan’s proposal to extend their water lot and add two new smaller floating drydocks and a work pontoon to their existing drydock operations.

“We expect to receive a decision from the port this spring,” Hounsell said. “This addition will allow Seaspan to expand our capacity for the number of projects we can take on at any one time.”

Bay Ship and Yacht

Alameda, Calif.-based Bay Ship and Yacht Co. worked double duty on some notable jobs recently and completed its first Tier 4 re-power project, CEO/Chief Naval Architect Joel Welter explained in an email.

BSY’s Syncrolift undocked and docked a pair of sister vessels from the U.S. Coast Guard, Robert Ward and Terrell Horne, on the same tide.

The two jobs were similar and were done back-to-back, Welter explained. The first boat arrived in September with the switchover occurring just before the Christmas season. Completion of the second boat is due to by the end of March, he noted.

“The syncro-yard, which is equipped with all required services and allows for exceptionally easy access from all directions, is ideal for vessel overhauls, especially exterior coatings work, structural repairs and stern gear work. These USCG jobs required all three,” he explained.

The Bay Area shipyard also had two research vessels in the drydocks at the same time last year. Scripps Institute’s Roger Revelle was docked on the HMB-1 and NOAA’s Rainier was docked on the AFDL-38.

The Rainier was outfitted with a new acoustic fairing (AKA gondola) on the dock floor that was fabricated and installed by BSY under the ship.

The company is continuing to do service-life extension program projects for U.S. Army landing-craft utility vessels with work almost complete on the second and third vessels, and work beginning on the fourth and fifth. They are also performing a major overhaul job on the Army’s LSV-4, USAV Lt. General William B. Bunker.

Bay Ship and Yacht also completed its first Tier 4 re-power recently by installing new Caterpillar 3512E diesels aboard Foss’s harbor tug, Alta June.

The yard’s engineering department provided detail design for this job in the months preceding the boat’s arrival and worked with Foss’ project engineer to fine-tune the arrangement, Welter said.

A tier 4 re-power adds many bulky equipment items and requires new tankage for liquid consumables, he explained. The five-month job was completed in August.

“After some slow years related to the pandemic, we are also seeing a resurgence in ferry and excursion vessel work as boats are brought back into service,” Welter said.

Upgrade work is being planned at the yard, as well.

“We are currently working on plans to increase our production space, reduce our emissions and acquire a larger crane to improve service to our drydocks,” he explained.

Marine Group Boat Works

The most significant change for Marine Group Boat Works’ yard was in April 2022 when the company re-powered its 665-ton Marine Travelift to a tier 4 John Deere engine. The family-owned boat repair and construction facility located near San Diego upgraded the piece of equipment to be more eco-friendly and exceed both state and federal standards.

This improvement to meet Tier 4 standards reduces particulate matter and nitrogen oxides released by the engine by about 90%, according to Marine Group officials.

The boatyard also recently wrapped up a big job with five vessels from Catalina Express, a family-owned business offering up to 30 roundtrips daily to/from California’s Catalina Island.

Catalina Express started the fleetwide engine re-power project with MGBW in 2022 with its high-speed catamaran, Catalina Jet, Marine Group Boat Works Director of Business Development Tim Cooper told Pacific Maritime.

The Caterpillar engines were re-powered to Tier 3 engines to fully comply with impending California Air Resources Board regulations. The project included a full high pressure water blast with new topside paint, installation of a new ride control system, renewing of shell plating, installation of new hydraulic lines and other tasks.

The remaining four vessels underwent engine re-powers in early 2023. The high-speed monohulls Catalina Express and Islander Express each received two new MTU Tier 3 engine packages which included all new cabling and controls, Cooper said. The engines that were removed from the vessels had low engine hours and were re-used for the re-power of two other high-speed monohulls, Avalon Express and Super Express.

The vessels also underwent general maintenance including shaft work, upgrading ride control components and rudder work. Three also received new paint jobs.

In another notable project, in August MGBW completed a $4.6 million contract for the Golden Gate Bridge, Highway and Transportation District to service and repair four high speed, aluminum passenger ferries from the San Francisco Bay area, the m/v Del Norte, m/v Mendocino, m/v Golden Gate and m/v Napa.

MGBW hauled, serviced and launched all four vessels. Each received routine maintenance and inspections required by the U.S. Coast Guard and upgrades to some systems, but the Del Norte and Mendocino projects were considerably more extensive and complex, according to Marine Group officials.

The Del Norte work included removal and replacement of four Marine Jet Power waterjet engines, updating communication systems and minor engine repair. Work on the Mendocino took more than 20,000 hours to complete and included major structural repairs that required removal of the superstructure from the hull.

The work was completed between late 2021 and mid-2022.

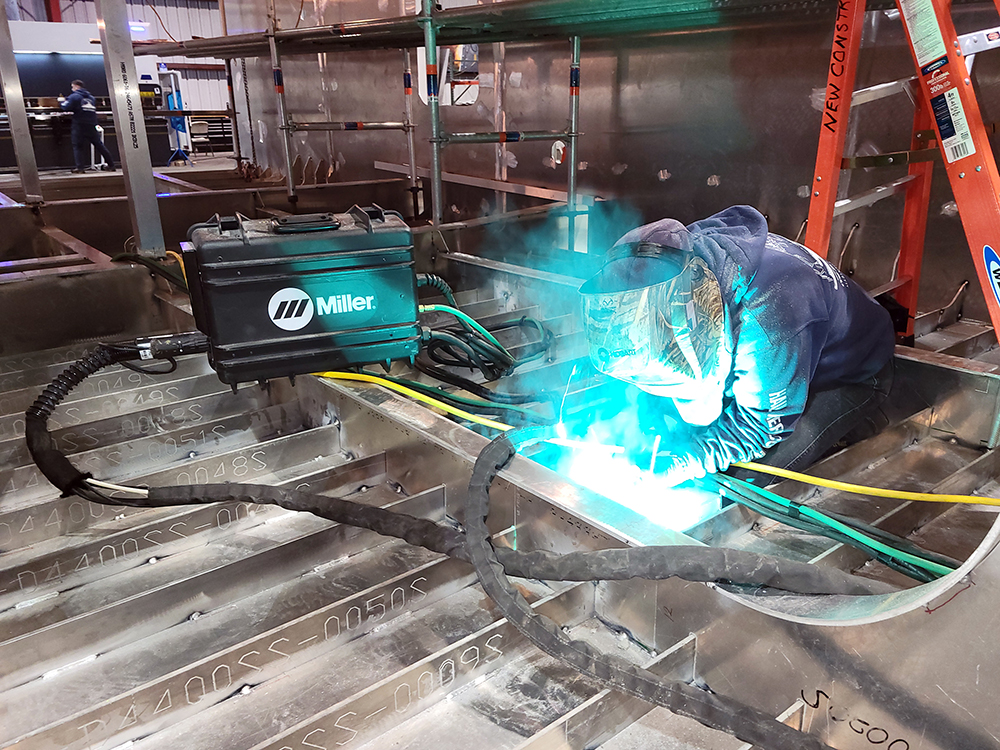

The most recent development for the shipyard is a new on-site training program. MGBW was awarded $524,058 from the U.S. Department of Transportation Maritime Administration’s Small Shipyards grant in 2021, with the funds helping the company launch an in-house welding certification program.

Pacific Fishermen Shipyard

Pacific Fishermen Shipyard, which has been servicing commercial vessels in Seattle since 1946, has recently gained substantial new business since a number of Pacific Northwest shipyards and repair facilities have closed, the shipyard’s Doug Dixon said.

The shipyard’s largest project was the re-planking of the 1922 steamer Virginia V last year, followed by the replacement of her sponsons this year, he noted. The 100-year-old vessel still serves thousands of people annually.

In February 2021, the historic ship pulled out of her home port at South Lake Union’s Historic Ships Wharf and headed to the shipyard. The haul out turned out to be more extensive than usual as fungus had invaded some of the wooden planks.

By March 2022, PFS shipwrights had installed a new stem and meticulously steamed and placed planks on the hull. The ship left the yard June 25.

Other major recent projects include stern trawler Alyeska’s controllable pitch shaft rebuild, Halvorsen tug Diane H’s new stern tubes and Pacific Mariner’s grounding damage repairs.

Vessels in for what Dixon calls a “shave and a haircut” (drydock and a fresh coat of anti-fouling paint) and miscellaneous welding repairs include Barbara J, Victoria Clipper V, Entrance Point, Early Dawn, Northern Prince, Rose Lee, Safari Quest, Sally Fox, San Juan Clipper, Sea Dragon, Sea Storm, Sunset Bay and Wilderness Discoverer.

Stabbert Marine and Industrial

The boatyard closures throughout the COVID-19 pandemic and more recently have brought new business to other facilities that have held strong, including Seattle-based Stabbert Marine and Industrial.

The results have been two-fold for Stabbert Marine, Business Development Manager Brian Galbraith said. The company has gained new work, primarily for the Puget Sound tug fleet, and has focused on converting vessels like the r/v Ocean Guardian from a platform supply vessel to multipurpose cable-lay vessel for SMI’s sister company, Ocean Services.

SMI Ballard has assisted its tug customers through their repair, maintenance and regulatory service work, Galbraith noted. The whitefish fleet also has been coming to SMI for repair and maintenance work on their vessels as they have continued to hold a strong market, he added.

The most notable development for SMI is that in February the Stabbert family finalized the purchase of the Lovric Sea-Craft property in Anacortes, Wash. and renamed it Stabbert Marine and Industrial Anacortes.

The site includes 580-feet of deepwater moorage pier space, 500-ton drydock, 500-ton railway and a 750-ton railway for haul-outs, Galbraith said. There’s also fabrication, wood and machine shops.

“SMI will continue to focus on servicing the PNW fishing, tug and commercial craft at this facility through vessel repair and maintenance, refits and conversions,” Galbraith said.

“Over the next couple of years,” he added, “we will be doing a lot of improvements to the facility such as upgrading the entire electrical system to be able to harbor larger vessels and provide proper power throughout the facility.”

Fred Wahl Marine Construction

Fred Wahl Marine Construction, based out of Reedsport, Ore., has been hard at work building quality commercial vessels and enhancing operations at their yard.

The most recent vessel construction is the f/v Uyak, Marine Designer Kendall Blake announced in an email. The new vessel, which is 68 feet by 29 feet and 5 inches, went into service in December.

The crabbing and shrimp vessel out of Reedsport was designed in-house with external engineering support, he explained.

“It’s got all the recent technology,” Blake said.

The company is now constructing its next vessel, a spec boat planned to be 58 feet by 28 feet and five inches.

“That’s kind of what we’re known for,” Blake said, adding that it should be done within the year.

In other yard work, the f/v Western Seas came in for new forward bulwarks and various other improvements. It turned out well, Blake said, and extended the life of the vessel.

Regarding yard operations, Fred Wahl Marine Construction recently increased its service abilities with the purchase of a new 300-ton lift from Ascom, which accompanies their Ascom 820-ton lift. The firm also recently completed a slip for small vessels that can be lifted using the 75-ton lift.

“The business is continuing to grow, our schedule is looking busy and we are hiring,” Blake said.

Al Larson Boat Shop

The biggest job at Al Larson Boat Shop in recent years is a re-power for Crowley Maritime on the tug Valor with a tier 4 Caterpillar 3516E engine, Project Manager Jeff Wall told Pacific Maritime.

“I believe it was the first Tier 4 re-power of its kind on the West Coast,” he said. “We did this job in 2020 (and) it was probably the most advanced re-powering job we’ve done so far.”

The project included changing out two main engines CAT 3516E, also three generator pumps and piping and hull modifications.

“These engines are the most advanced cleanest running engines to date,” Wall said.

The new 3516E tier 4 main engines are about 20,000 pounds each. The vessel later headed to drydock for finishing touches.

In 2022, the shop worked on a variety of jobs, including installation of new main engines on the 95-foot charter vessel Dana Pride; retrofit of engine room re-powering with new Cummins diesel engines and a new generator, hydraulics and controls for Manson Construction’s PUP; completion of minor maintenance and a paint job for the Jankovich Co.’s liquid tank barge JAKE J, and installation of a Z-drive propulsion overhaul and maintenance on the tug Simone Brusco.

Also, Al Larson finished sandblasting and painting a fire boat for the Port of Long Beach earlier this year.

Everett Ship Repair/Nichols Bros.

There’s been a focus on supporting passenger vessels and ferries, as well as expanding operations, at Washington-based sister companies Everett Ship Repair (ESR) and Nichols Bros. Boat Builders (NBBB).

Lindblad Expeditions recently placed the Nichols Bros.-built m/v National Geographic Venture cruise ship in ESR’s new Faithful Servant drydock for regulatory inspections and standard drydocking, officials said Feb. 1.

At the same time, Everett Ship Repair was preparing the m/v Cathlamet for an emergency repair job for Washington State Ferries. They installed the new pickle fork modules and conducted some drydock repairs prior to mooring the vessel pier-side for final completion.

Kitsap Transit’s m/v Solano, formerly owned and operated by San Francisco Bay Ferries WETA, is undergoing an extensive overhaul of machinery equipment, gearboxes, main engines, generators and jet thrusters.

Outfitting includes an all-new custom console with state-of-the-art navigation electronics, latest interior finishes and seating throughout.

Nichols Bros. Boat Builders also completed other major upgrades for m/v Catalina Flyer and the m/v Glacier Express.

Everett Ship Repair recently purchased two new 40,000 psi ultra-high-pressure water blasting systems that were delivered in March of 2022. UHP water blasting is a cost effective and environmentally friendly alternative to abrasive solid blasting material. It also minimizes labor and waste stream produced by traditional grit blasting.

Also, last March, Everett Ship Repair expanded its operations with a second drydock and the addition of a floating crane barge.

The drydock Emerald Lifter has a lifting capacity of 2,000 tons and working deck area of 220 feet by 62 feet. The new 150-ton capacity floating crane services both the new drydock and the yard’s other drydock, Faithful Servant.

Ventura Harbor Boatyard

Ventura Harbor Boatyard is a larger 4.5-acre facility that utilizes two travelifts, a 35-ton Marine Travelift servicing the small vessel boatyard and a 220-ton Marine Travelift servicing the adjacent large vessel boatyard.

The yard regularly performs services for the National Park Service vessels Sea Ranger and Ocean Ranger and local tourist vessels.

Crews at the boatyard have been working on both commercial and pleasure vessels while the yard goes through some notable management changes. After recently transitioning from the now-closed Gambol Industries in Long Beach, Calif., VHBY Chief Executive Officer and General Manager John Bridwell has plans to expand the Ventura yard’s service capabilities and client basis.

Also, in early 2022, m/v Vision, an adventure vessel with Channel Islands Expedition, and Raptor, with Raptor Dive Charters, were both hauled out at Ventura Harbor Boatyard for maintenance to prepare for the season.

Sara Hall has 15 years of experience at several regional and national magazines, online news outlets, and daily and weekly newspapers, where coverage has included reporting on local harbor activities, marine-based news, and regional and state coastal agencies. Her work has included photography, writing, design and layout.