The innovation of deck machinery is an ever-present force in the maritime industry.

While a winch will always be a winch, a newer model may pack the same power in a smaller footprint. A crane is always a crane, but the modern version may be all-electric. And the list goes on. Herein some of the deck machinery industry’s major players discuss their newest and best-selling products as well as industry trends.

Markey Machine

Seattle-based Markey Machine saw an ownership shift late last year, closing a growth investment with Christian Schiller and Brian Bogen.

“The new ownership arrangement offers many advantages, particularly in the area of future growth of Markey,” according to Scott Atkinson, Markey Machine’s vice president of business development. “Markey’s renowned reliability is the main reason it has just announced that it is going to a three-year warranty for its winch lines, whereas standard in the industry is one year or 18 months.”

Markey received accolades last May when the company was one of five finalists for the prestigious Innovation Award at the TugTechnology Conference held in Rotterdam, Netherlands.

“This was for our newest escort winch design, the Agile Concept, which has been a smash hit,” Atkinson said.

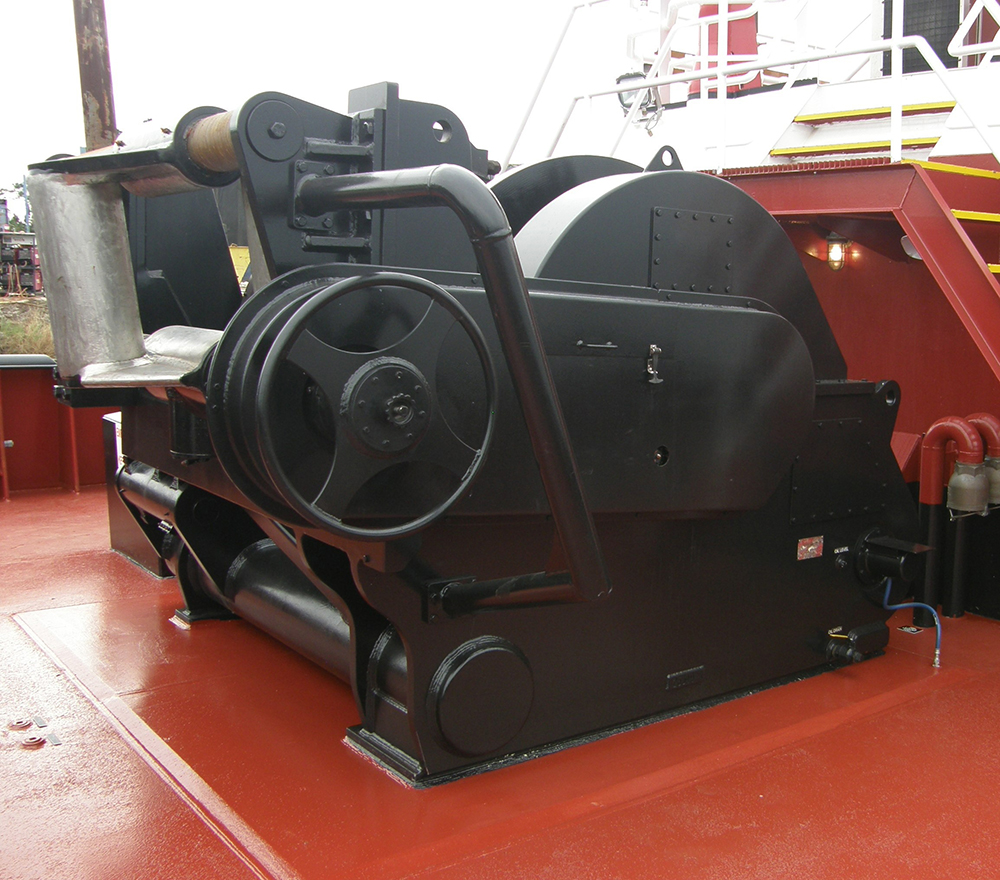

The award-winning new Agile Concept is an escort-operations, bow-mounted winch. At the time of this writing, four long-time clients recently placed orders, Markey has said.

“In those cases where space between in the staple and the ship-escort hawser winch is small, the Agile Concept is ideal, as it marks a significant design revision,” Atkinson explained. The athwartships dimension is reduced from earlier designs, and the L-shaped gearbox, which had been independent of the winch, is joined integrally with the winch. The winch features a reduction of 16.4% over the previous model.

“Markey’s winches have retained their very high quality, while responding to changes in tug design,” Tim McCallum, senior vice president of engineering, technical and economics at Signet Maritime, noted in a news release. “We were looking for weight reduction and a modified footprint, while retaining the Class III escort winch features and the renowned winch control system,” he added, referring to Markey’s Render/Recover winch control.

Another new product of note is the new DESH-5 Two-Sheave Level Wind. According to Atkinson, the unit is designed from varied processes in earlier three-sheave units while enhancing safety features.

For example, the unit has no reverse bends in the cable path, thereby lengthening cable-service life. In addition, the need for a winch turntable (platform) is eliminated by use of rotating flagging sheaves. Mechanical actuation, by use of a hand-wheel directly coupled to the diamond screw, significantly reduces overall level-wind cost and complexity in the absence of extra sensors, motors and variable frequency drives (VFDs).

This new level wind has been recently ordered by the National Oceanic and Atmospheric Administration to be used aboard the r/v Ron W. Brown as part of an overall upgrade effort for the vessel.

Presently the winch hawser winches, from the DEPC-32 up through the DEPCF-52, are the company’s best sellers in both Class II and Class III configurations. Towing and mooring winches have also sold well, according to the company, while oceanographic and hydrographic winches have sold solidly in the deep-sea sector.

“One trend we see is that as other winch manufacturers struggle to retain field staff for the after-market part of the winch business,” Atkinson noted. “Markey is blessed to have a remarkable team—about which we have only recently gone public—for after-market support.” The new Sentinel Survey division also has proven a success largely because demand has grown.

Integrity Machining

Integrity Machining, a Marysville, Wash.-based supplier of Kolstrand, JKFAB, NORDIC and Forfjord marine equipment, reports several developments across their brands, notably a partnership with EZ Puller to become a supplier of their electric gurdies. A new Forfjord #2, 28-pound anchor for smaller vessels will be released later this year. Integrity, whose roots stretch back to 1929, also has partnered with Tylaska to develop the Tylaska T40 rigged release.

“Previously the largest offering was the T30 rigged release, but numerous inquiries pushed us to develop this monster release,” Integrity Machining Executive Director Rachel Kaiser wrote. The T30 is rated at 20,000 pounds working load and 40,000 pounds maximum load.

“Tylaska USA made quality and performance,” she explained. “This shackle will stand the test of the most extreme fishing situations as well as the confidence of the operator. Safety lock pin included.”

Additionally, the company is offering a redesigned Power Block Control Valve. Fully marinized values are offered in three configurations: power grip control only, power grip and two-speed motor control and power grip with two-speed motor and tilt control.

This year also saw the release of a popular new 3-Spool Trolling Gurdy Valve. Integrity Machining reports that their bestsellers include NORDIC Clutched Winches, Kolstrand Purse Dominators, Kolstrand Power Blocks and aluminum ring hooks.

Trends on the commercial fishing side include longliner clients using NORDIC haulers choosing to go with the 4.8:1 gearbox conversion to increase torque and speed when hauling slinky pots. Salmon trollers are generally moving away from legacy brass and nylon-trolling gurdies to the Kolstrand all stainless steel Gurdy Wizard. The Gurdy Wizard comes in both two- and three-spool configurations.

Notably Integrity Machining built a 32-inch NORDIC Clutched Anchor Winch for the r/v Western Flyer of Steinbeck fame last fall.

La Conner Maritime Service

In 1978, Ed Oczkewicz established Maritime Fabrications in his parents’ backyard in Marysville, Wash., complete with a renovated chicken coop for an office. The company later moved to Conway, Wash., and expanded into boatbuilding and more. In 1993, Maritime Fabrications acquired the assets of La Conner Machine and Drydock, moved out of its previous Conway location, and began operations under the La Conner Maritime Service brand, broadening its boat service and repair capabilities.

“We are partnering with Marine Hydraulic Consultancy again to build a second gillnet drum for the Bristol Bay fishery,” Isaac Oczkewicz of Maritime Fabrications told Pacific Maritime. “We partnered with them last winter and produced a gillnet drum with new and improved design features, which was successfully used in Bristol Bay during the 2023 season.”

The new piece of deck machinery was installed on the f/v Abundance.

“This newbuild is a bow/stern picker with a full flush deck and twin jet drives and was the perfect candidate to use the new and unique features of this new net drum assembly,” the consultancy’s Alan Severns explained.

“This net drum assembly was mounted on a 180-degree rotating base and will also have a pivoting level wind,” he stated. “To eliminate the hoses on the deck when sliding the net drum from bow to stern, there (were) multi-port quick disconnects on either end, (which) will eliminate all hoses on deck.”

Additionally, the rotating level wind was improved by adding a rotating swivel manifold to clean up the plumbing supply.

The company’s automatic level winds continue to be a popular go-to piece of equipment for many fishermen. Maritime Fabrications’ Big Bay roller is an improved-upon design of their standard stern roller that reportedly has been gaining popularity since it was introduced a few years ago.

“It offers some significant advantages over the standard rollers, in strength, functionality and ease of maintenance,” Oczkewicz stated. “Our rotator gillnet drum has also become the go-to option for many of the new bow-stern picker style Bristol Bay boats being built. It has undergone many refinements that make it simpler to use, easier to maintain, and safer.”

Naust Marine

Naust Marine is an Iceland-based marine electric winch, control and power management solutions company that was founded in 1993 with their Automatic Trawl Winch (ATW) control system for electric winches. The company has operated a Seattle sales and service office since 2011 and a production facility in Spain since 2018.

The company is growing with a new 2022 office in Ísafjörður, Iceland, and is expanding its Spanish facilities for a 30% increase in production capacity and testing of larger deck machinery in-house, notably pedestal cranes.

A project with fishing gear company Hampiðjan called for designing a new net sounder winch for Hampiðjan’s fiber optic cable.

“Conventional overhead cable reels are not suitable for Hampiðjan’s newly designed fiber optic cable, so Naust Marine is currently constructing a winch that will work with this innovative technology,” Regional Manager Brittany Tassano told Pacific Maritime. “This solution will allow for an almost unlimited amount of data from cameras and other electronic equipment at a speed previously unknown in the marine industry.”

Trend-wise, Naust notes an increased demand for winches that maintain performance but are smaller and lighter. Naust’s response is to make winches with a smaller footprint and greater fuel consumption efficiency. The company’s winches also integrate the motors into the winches for a more compact unit.

“The electric approach to trawling, given the many advantages, is also lending to more and more companies retrofitting and building with electric solutions,” Tassano explained.

Stated benefits of electric trawling equipment include compatibility with modern green operations, no potential for hyrdaulic leaks and quieter and cleaner operations.

Sales-wise, winches remain the company‘s bread and butter. Naust reports that its best-selling products include its tried and true ATW control system that‘s currently installed on around 140 vessels worldwide.

According to Tassano, the market‘s demanding more from their deck machinery control systems, namely more data input in the form of alarms, GPS and generally near-constant communication.

Naust touts its VFDs, rectifiers and other electronics to allow those aboard to handle variable speeds. Naust Marine’s in-house developed ESG Level Wind—electrically-driven and electronically synchronized—is integral to their trawl winches.

MacGregor

MacGregor is a deck machinery and vessel services company, owned by Helsinki, Finland-based Cargotec since 2005. The firm‘s roots date to 1937 when Macgregor & Co. was founded in Whitley Bay on the northeast coast of England.

In April, Cargotec’s board of directors appointed Casimir Lindholm the company’s new President and CEO.

“With a talented team, a strong portfolio of businesses with decision making close to customers and a commitment to sustainability and profitable growth, I believe that the company is in an excellent position to create value by empowering our businesses even further in the years to come,” Lindholm said in a news release.

Among the many MacGregor products are the company’s electric cranes. MacGregor has delivered more than 600 electric cranes since 2007.

MacGregor has said that its next generation electric crane is 15% more efficient than the first generation and up to 50% more efficient compared to the traditional closed-loop hydraulic design. Electric drives are available for all merchant cranes in the MacGregor portfolio, including port, bulk, container, multi-purpose and heavy lift cranes.

The company touts its newer Heavy Lift Crane-Electric (HCE). Among the stated benefits include weight optimization, improved reliability and safety with redundant power supply units and additional brakes, and up to 50% lower energy consumption. The crane has up to SWL 1,000 tons.

The Generation 2 Drive System is another product series of note. The design is based on the latest generation of water-cooled electric motors and inverters. It includes a direct motor connection for further improved power efficiency due to less power transmission loss.

The company’s OnWatch Scout increases the flow of information and moves support from a reactive to proactive mode, with operational data streamed directly from the vessel, monitored, analyzed and used to provide guidance on performance.

Norris Comer is a Seattle-based writer and author. His debut memoir, Salmon in the Seine: Alaskan Memories of Life, Death, & Everything In-Between is now available wherever books are sold. You can find him on Substack, Instagram and at norriscomer.com. He can be reached via email at norriscomer@substack.com.