Schedule predictability is always at the top of the commuter’s list of demands, so for ferry operators, staying on schedule is crucial. If a ferry sails a couple of hours late, the impact on passengers is significant.

To maximize reliability of their fleets, ferry operators demand exceptional dependability from their installed equipment and integrity of energy sources—including the assurance of guaranteed fuel supplies. If there is even the slightest question about reliability, availability or cost effectiveness related to fuel energy, then operators will demand alternative energy options such as back-up generators, energy storage at terminals and/or hybrid engines that burn clean fuels.

Fuel technology has changed a lot over the last 40 years and the next 40 will see even greater change—an important consideration when ferries in North America generally operate for more than 30 years.

To guard against current energy volatility and accommodate evolving future fuel sources, some operators are opting to fit energy-source flexibility into their newbuild designs.

Including such flexibility when shaping vessel design means that predicted future technologies can be affordably adopted with minimal conversion costs when the technology is there to warrant it.

The opportunity to upgrade to new technologies—particularly decarbonizing technologies—can only be met by designing the vessel with this in mind.

The Current Thinking

A common refrain from ferry operators and designers today is that the jetty shore charging infrastructure and electrical utility connections do not yet exist to leverage energy from shore.

As a result, diesel-powered ferries still make up many of the new vessels coming online today. Unfortunately, most of these new boats are not designed for easy conversion to take advantage of eventual shore-charging solutions.

Another reason given for the current commitment to diesel-powered vessels is that shore energy as currently available is not efficient enough to be considered ‘green’. This approach ignores initiatives already underway to increase battery life and efficiency and adapt shoreside energy grids to accommodate the move from fossil fuels to electric alternatives.

Planning for the Future

Though a commitment to diesel-only design is the current norm, there are some very good examples of forward thinking in new ferries being delivered to North America today, even if the need for future-proof technology has not yet been universally accepted.

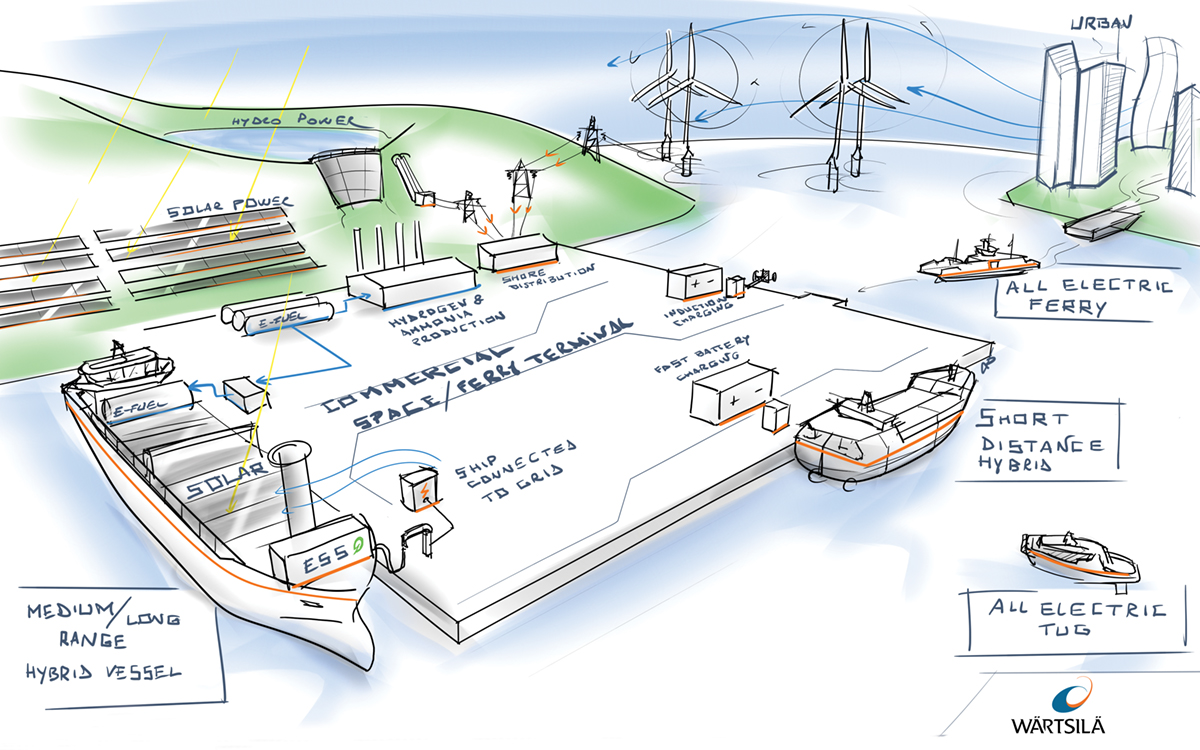

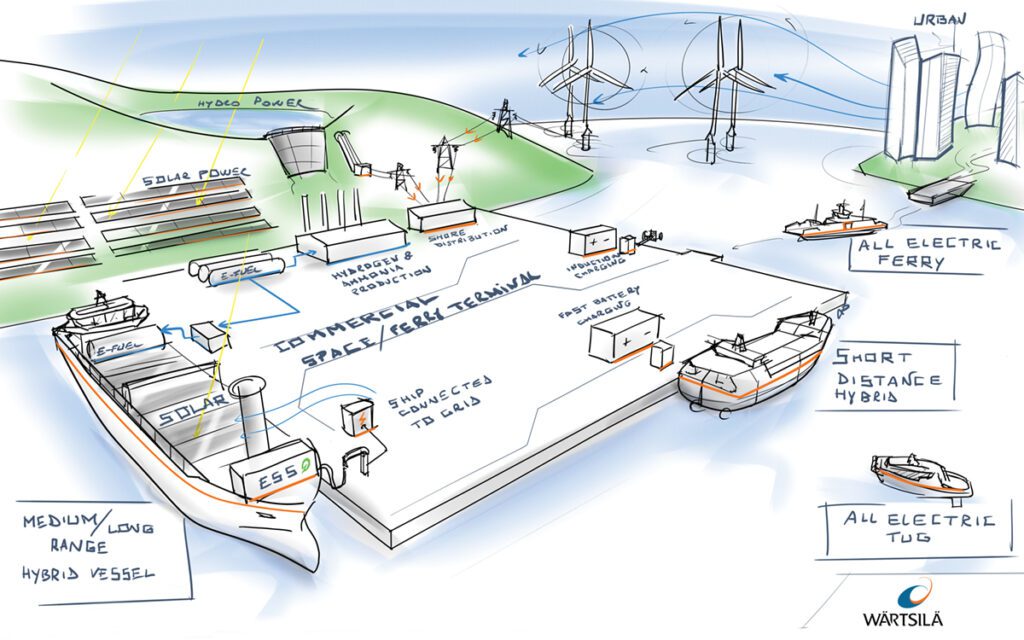

An example of a ‘bridge’ solution between the current state of affairs and the ‘next-gen’ technologies still in development is the move toward designing diesel-electric hybrid ferries with an electrical system that allows for future additional battery capacity, integration of energy sources such as fuel cells and connections to shore charging.

A hybrid system delivered today brings optimization benefits for best operational efficiency across an engine’s lifetime, regardless of the source powering that engine.

Battery replacement can be expected after about 10 years, and as battery technologies are evolving quickly, hybrid designs allow for conversion to the right battery at the right time throughout the expected useful life of the vessel. Potentially more efficient, more power-dense and less costly battery solutions will exist, and flexibility in the design of the electrical system allows the technology to be upgraded as part of the battery replacement cycle.

The choice of internal combustion engine and fuel type is also critical in the initial design of the vessel. Choosing diesel engines gives the flexibility to use biodiesel, methanol and even ammonia. Choosing dual fuel engines in the initial design opens the door to gaseous fuels such as LNG, synthetic methane ammonia and hydrogen.

The latest generation of engines allow for conversion between liquid and gaseous fuels with only a moderate investment. To be truly flexible in the adoption of future fuels, ferry designs need to allow for different fuel storage and handling systems.

Ensuring Efficiency

Regardless of the fuel types and energy sources selected, vessel design must be as efficient as possible. Improving efficiency reduces the amount of energy used. Energy is expensive, whether onshore electrical energy or fuels for engines or fuel cells, and energy availability and storage impact the operational profile of the vessel. Most recent advances in efficiency technologies are now available for design integration, such as propeller technologies, advanced hull designs, air lubrication systems and high-efficiency rudders and thrusters. Investing in these technologies brings operational benefits, but also allows for the adoption of future fuels and energy sources that may be constrained by available fuel space or shore charging times.

The ‘next-gen’ operator will recognize the speed of change in the world or ferry propulsion and design. The naval architects and designers serving the new generation of vessel operators must also consider the rapid evolutionary development of marine transit and design their ‘next-gen’ vessels accordingly.

Mark Keneford is the managing director of Wärtsilä Canada. Wärtsilä is developing flexible technologies that support the design and build of future-proof ferries. Mark will be sharing his thoughts on the viability of ‘future-proof’ ferries at Ferries Conference 2022 in Seattle on Sept. 22.