Wolverine Terminals, an Alberta, Canada-based company focused on the development of energy-related marine terminals at ports in Canada and the U.S., has begun the development of Prince Rupert Marine Fuels, a marine fuel delivery service for the Port of Prince Rupert in British Columbia.

Mobilization and the initiation of construction activities in Prince Rupert began in early December, with Vancouver Pile Driving as the major contractor responsible for construction of the mooring.

Prince Rupert is one of the few major global ports to not offer marine fueling service for cargo ships. In the absence of such services at the port, cargo ships must carry enough fuel to make a round trip or detour to an alternative West Coast port, such as the Port of Vancouver, to fuel. The additional fuel carried to make the round trip displaces potential cargo and drives up shipping cost.

In 2020, 537 vessels visited the Port of Prince Rupert, and that number is forecasted to grow in the years to come, so having a local fuel service, according to Wolverine Terminals, assists in achieving this forecasted growth.

Types of vessels that visit the port include cruise ships, cargo ships, ferries, fishing vessels and private boats. The scope of the project includes fuel associated with cargo ships and ferries.

Aside from the lack of fuel, the port has many strategic advantages that would help support future growth; it is the closest North American port to Asia, and has the deepest natural harbor in North America. The port also has direct access to a rail network with connections to markets across North America and significant capacity to increase traffic volumes.

The port, which is under the jurisdiction of the Prince Rupert Port Authority (PRPA), which is mandated to support Canada’s trade activity by facilitating and expanding the movement of cargo and passengers within the port.

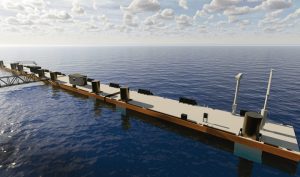

Wolverine Terminals’ Prince Rupert Marine Fuels project includes three main components: a marine berth, a rail barge and a fuel distribution barge.

The marine berth would be capable of securing the rail barge and distribution barge. Wolverine would use the existing “Aquatrain” loading ramp at the port to load rail cars onto the rail barge. The 142-meter (466-foot) barge would be able to accommodate up to 24 rail tank cars on deck.

Additionally, there would be a peripheral coaming surrounding the entire deck, as well as spill response equipment on board and a floating containment boom surrounding the barge.

Motorized engines would be equipped with residential mufflers for noise suppression. Odor and air emissions would be mitigated, and light emissions would be minimized through the use of flat lens light standards, according to Wolverine Terminals.

The fuel distribution barge design would also conform to industry best practices and minimize air, noise, and light emissions, according to Wolverine.

It would have a capacity of about 4,800 metric tons and measure about 78 meters (256 feet) in length.

“The barge will be equipped,” Wolverine Terminals said in a statement, “with a deck mounted container with spill response equipment for rapid deployment. The fuel distribution barge will be a modern double-hulled vessel. Motorized engines will be designed to best industry standards to minimize noise and air emissions.

The company also said that its fuel tanks would meet requirements in the International Convention for the Prevention of Pollution from Ships (MARPOL), as well as Transport Canada regulations.

Project Summary

Construction of a new mooring site at an existing marine industrial location to secure fuel barges:

- The marine berth would be the mooring site for the rail barge and transfer of fuel to the distribution barge;

- The rail barge would only move between the marine berth and the Aquatrain Terminal;

- The distribution barge would move between the marine berth and fueling locations within the port.

- Operation of a marine fueling service that involves:

- The transfer of rail cars on and off a purpose-built rail barge at the existing Aquatrain Terminal;

- Tug transport of the rail barge (about 400 meters/1,312 feet) between the Aquatrain Terminal and the fuel service mooring site;

- The transfer of marine fuel from rail cars into fuel storage tanks located within the rail barge and within the fuel distribution barge;

- Transfer of marine fuel from rail barge to the fuel distribution barge;

- Tug transport of the fuel distribution barge between the fuel service mooring site and approved locations within the port;

- Transfer of fuels from the fuel distribution barge into large cargo vessels.

Vessel construction is being managed by Damen Shipyards Group and is underway at its Vietnam facilities. Wolverine has said that it anticipates beginning fuel delivery operations at the port in early 2023.