By Peter Marsh

Munson Builds High-Speed Skimmer for Oil Spill Contractor

Located 400 miles north of Fairbanks on Alaska’s north slope, Prudhoe Bay, Alaska is home to the largest oil field in North America. The regional oil spill response contractor, Alaska Clean Seas, maintains about 60 miles of oil containment boom and more than 100 specialized response vessels.

The latest of these vessels is the 48-foot x 16-foot Pt. McIntyre, a Munson purpose-built oil aluminum skimmer designed to operate in the harsh environment above the Arctic Circle.

It is based on a standard landing craft hull that company founder Bill Munson pioneered in the 1980s and that his son Jesse continues to refine to suit customer requirements after 35 years with hundreds delivered to oil companies all over the world as boom boats, skimmers and utility boats.

Pt. McIntyre is powered by a pair of Volvo Tier 3 D13 diesels. The 12.8-liter, 6-cylinder engine is rated at 800 hp (commercial duty) at 2300 rpm and features a twin-entry turbo and the latest electronic control system for increased load-carrying capability, rapid acceleration and low fuel consumption.

Propulsion is by twin Hamilton HJ403 Water Jets with a maximum rating of 1200 hp. Top speed is 34 knots (39 mph). One Volvo engine with a PTO powers the integrated hydraulic system rated for 100GPM at 3700 psi. Fuel capacity is 500 gallons.

The main engines and the generator are provided with keel cooling with dry exhaust, which also supplies heat to the main cabin; the enclosed wheelhouse is fitted with electric heaters. The helm is equipped with Glendenning engine controls with a ProPilot joystick for simplified maneuvering when in skimming mode.

The deck is outfitted with a pair of Maxilift hydraulic deck cranes port and starboard by Next Hydraulics from Italy, which are necessary to position the rigid aluminum outriggers that hold the oil boom in place. There are hydraulic capstans and anchor winches at the bow and stern, with hydraulic quick disconnections to the oil skimmers, a boom roller, and Desmi 250 transfer pump.

The vessel’s also equipped with a pair of floating disc skimmers, but it can carry and deploy other types, depending on the oil type and sea state.

“Alaska Clean Seas has several Munson Boats from the 1980s and ‘90s. The time had finally come for them to upgrade to a serious workboat capable of going further offshore as they expand drilling operations east and west from Prudhoe Bay,” Munson Boats CEO Jesse Munson explained. “This hull shape takes maximum advantage of the bow ramp and V-hull to carry heavy loads at high speeds through rough water.”

“The push knees and capstans allow the crew to position oil-recovery barges up to 100 feet, while the bow ramp and shallow draft permits the oil boom or pipes to be laid onto the shore or to connect with land-based equipment,” he pointed out.

Jones Marine Commissions McIlwain-Designed Sylte Tug

Jones Marine Group was founded in British Columbia in 1991 by company president Daryl R. Jones with one small tug towing logs rafts. He now manages a fleet of eight towboats and commissioned his first ASD tractor tug from Sylte Shipyard in 2016. The 53-foot x 26.5-foot x 14-foot design came from local naval architect A.G. McIlwain Ltd., who has been in business since 1967 and is responsible for many small tugs working the inland waters of B.C.

McIlwain has completed a type of small ship-handling tug (50-to-65-foot long) suitable for the many log loading operations along the remote BC coastline. Sylte has specialized in building this type and has been producing about one per year since the early 2000s.

The boats all have a distinctive appearance, with a very low beam-to-length ration of 1:2 and a raised forecastle to comply with Canadian regulations that require all accommodations to be above the waterline.

The beam offers notable stability, according to the company, while the length allows the tug to work in tight spaces. The pilots are all accustomed to having tractor tugs to assist them in Vancouver, and now they expect to have the same type of tugs in Nanaimo, the main port on the central coast of Vancouver Island, Jones explained.

His first ASD design, the 53-foot David J, was fitted with twin 1200 hp diesels, and began ship assist work from the company base in the small port of Chemainus.

This boat was so successful that Jones soon began planning for a sister ship, but reckoned the hull could take a lot more power. McIlwain agreed and Sylte, which is also family-owned, began work on the Judy J in 2019. Externally it was identical, but is notable for a 50% increase in output from a pair of MTU 12V4000’s rated at 1700 hp each for a total output of 3400 hp. (They are certified in Canada as “IMO Tier II,” equivalent to EPA Tier 3.) The ASDs are Kongsberg US 155 P14 with carbon-fiber shafts and soft engine mountings to isolate vibrations and noise.

Auxiliary power is provided by a pair of Caterpillar C4.4 gen-sets, which also drive the hawser winch from Burrard Iron Works of Vancouver. Like the rest of the Jones Marine fleet, the Judy J will operate as a two-person day boat, with remote winch controls to allow the crew to work the boat from the helm or the foredeck.

Jones said he believes that this pair of dedicated ship handlers can manage any ship that could call at Nanaimo, including log ships, car carriers and mid-size cruise ships.

Dakota Creek Delivers RAL-Designed Navy Tugs

Dakota Creek shipyard in Anacortes, Wash. has delivered two of six YT 808-class tugs ordered by the U.S. Navy, with these going to the Naval Base Kitsap in Bremerton on the west side of Puget Sound. This contract is notable as the first to be propelled by Caterpillar Tier 4 diesels with the latest SCR system to reduce emissions, and also for the naval architects chosen: the world-leading tug specialists Robert Allan Ltd. (RAL) of Vancouver, Canada.

The new design replaces the Navy’s 45-to–55-year-old YTB class tugs at the Portsmouth Naval Shipyard in Maine and the Pacific Northwest, and will perform ship-handling duties for the full range of U.S. Navy surface ships, barges and submarines.

The YT 808 is based upon the RAL Z-Tech 4500, which the Navy has been operating since 2010 in the Pacific Northwest and Japanese waters as the Valiant (YT 802) class. Six have been in continuous operation for the last decade and the new vessels (YT 808) have modifications based several factors, including: experience with them; new Navy requirements; and deckhouse changes to house the significantly larger exhaust emission systems required for Tier 4. The hull form for the new vessels remains essentially identical to previous versions.

The tugs are also equipped with a 2,000 GPM fire pump and two monitors, and have the following particulars:

Overall length: 27.42 m (89.96 feet)

Molded beam: 11.65 m (38.22 feet)

Molded depth: 5 m (16.4 feet)

Overall maximum draft: 4.88 m (16 feet)

Machinery: CAT 3512E Main engines Schottel model 340 Z-Drives

Power: 2 x 1810 BHP at 1,600 rpm

Bollard pull: 40 metric tons minimum

Free running speed: 12.5 knots minimum

Endurance: Seven days underway at 10 knots

The tugs are configured essentially as ‘day boats,’ but also provide accommodation for a crew of up to six people. One of the unique features of the layout is the complete separation of the accommodation deckhouse from the machinery casing, a configuration designed to both provide a reasonably dry access to the accommodation spaces in the notoriously damp north-west climate, as well as provide a significant degree of noise attenuation in the crew spaces.

The tugs are also equipped with a telescoping gangway, or brow, stowed across the aft end of the deckhouse, to use for transfer of personnel to other ships or down to submarines.

Changes to the fendering system are to incorporate feedback from operators on existing vessels. The fendering system at the bow consists of two rows of cylindrical fenders and a lower course of ‘W’ fenders. An extensive amount of underwater fendering is used for operation with submarines, and new diagonal “D” side fendering was added to help safely push low freeboard barges.

WCT Delivers Mini Tug for Snake River Lock Maintenance

The U.S. Army Corps of Engineers operates eight dams on the Columbia and Snake rivers, which maintain the inland barge route 365 miles from Vancouver, Washington to Lewiston, Idaho. The standard size for the locks is 650 feet long x 85 feet wide, and this waterway is the top exporter of wheat in the U.S.

About six tows pass through the Columbia River locks every day on average, and to maintain the lock system, there was a system-wide closure of all eight locks from March 6-21. Each dam has a small fleet of workboats to perform the tasks involved with delivering tools and materials to the locks, and placing temporary barriers to allow full inspection of the lock gates and sills.

In 2020, bids were invited to build a truckable 26-foot tug/utility boat for the Little Goose Dam on the Snake River to replace an older craft. WCT Marine & Construction of Tongue Point, Oregon submitted a design from Tullio Celano of Crescere Marine Engineering in Scappoose, Oregon capable of handling the bulkhead stoplogs.

“These are more like small drydock caissons that are floated into place with the assistance of the tug,” Celano explained.

WCT won the contract and built the boat over the winter of 2020-21. The steel plating for the hull was CNC-cut and assembled on a jig to ensure precise alignment of the frames and twin Cummins Tier 3 turbocharged 6.7 QSB engines, each rated 300 bhp (224.5kW) each at high output, producing a bollard pull of about five tons. Each engine turns a horizontal driveshaft connected to an open, four-bladed, 813mm x 508mm Workhorse propeller via a ZF 325-I gear with 2.957:1 reduction.

The wide beam provides full space in the engine room for such a compact hull. The engines are cooled by Fernstrum coolers mounted into recesses in the hull sides. Fuel capacity is 350 gallons and steering is by jog stick. The loaded draft is only five feet (1.5 meters) with the 26-foot length including full-size push knees, and the 13-foot beam (about four meters) and low pilothouse allow it to be transported on state highways. The tug has been classed by ABS and meets U.S. Coast Guard CFR rules for towing stability at full power. The hull features four heavy lifting eyes for launching by a small crane.

Modutech Wins U.S. Navy Tug Contract

Modutech Marine Inc. of Tacoma, Wash., which has a record of building a large number of small tugs for the U.S. Navy, has won a contract to design and build a prototype to replace a class of traditional Navy yard tugs designated YTL. Robert Allan Ltd. was selected to create a version of its 63-foot RAscal 1800-Z, to be designated the YTL 815 class.

This will be very similar, Modutech has said, to the standard design that has resulted in 10 or more hulls built outside the U.S. for international clients.

The design for the U.S. Navy includes updates to accommodate EPA Tier 4 engines and extensive fendering above and below the waterline to handle U.S. Navy surface ships, submarines and barges. The contract includes an option for a second vessel.

Details of the YTL 815:

Overall length: 19.2 m (63 feet)

Molded beam: 9.4 m (30.84 feet)

Molded depth: 3.5 m (11.48 feet)

Power: 2 x 970kW (1,300 hp)

Bollard Pull: 30 metric tons

Twin Caterpillar C-32 Tier 4 970 kW diesels with SCR exhaust system.

Schottel SRP 270’s Rudderpropeller ASDs with new SDC40 nozzle

Fixed pitch 1.85m-diameter propellers

C-4 Generators. CAT engine package

Modutech previously delivered a total of 30 small tugs to the Navy beginning in 2017 under two different contracts. The first was for 25 multi-purpose yard tugs, completed at a rate of about one a month. These craft measured 30 feet x 15 feet x 5.5 feet and were designated Work Boat Medium. They were designed by local naval architects Hockema & Whalen and Associates and were powered by a pair of Cummins QSL 9 diesels each delivering 285 HP that provided a 7.9-ton bollard pull.

In 2020, Modutech completed five 25-foot x 14-foot specialized submarine docking tugs which were delivered to Portsmouth Naval Shipyard in Kittery, Maine. These craft are powered by a single 450 hp (335 kW) Tier 3 Cummins QSM-11, turning one of the smallest ASDs made by Schottel with a 1m-diameter propeller that produces a static bollard pull of 11,500 lbs.

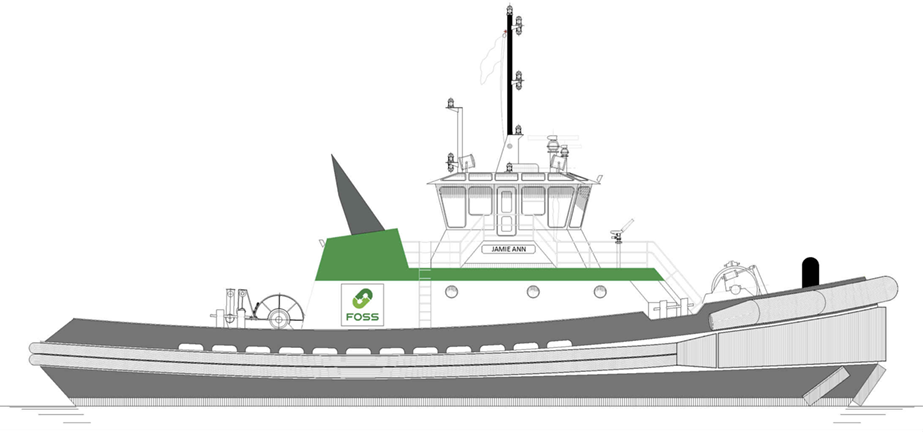

Nichols Bros. Finishing Last Foss 100-Footer

Nichols Brothers Boat Builders on Whidbey Island, Wash. is completing the last of four 100-foot x 40-foot ASD-90-class tugs for Foss Maritime from a design by Jensen Maritime Consultants of Seattle. This is an update of the Valor class that NBBB previously built 10 of for Bay Delta and other operators.

Each tug is equipped with a pair of MTU series 4000 M65L Tier 4 main engines, with a combined power of 6,866-hp, coupled to Kongsberg US255 azimuth thrusters, which produces over 90 tons of bollard pull. There are three John Deere gensets, two generating 120 kW and a third unit producing 65 kW.

Markey Machinery of Seattle supplied two winches: the first two tugs were fitted with a 75-hp single-drum DEPGF-52R electric winch on the bow for ship assist. It holds over 500 feet of nine-inch high-strength line.

On the aft deck for ship towing and rescue is a double-drum Markey TESS-34AS with 2,600 feet of 2.25-inch wire and 440 feet of seven-inch synthetic line. The second pair of tugs have a smaller aft winch for barge towing.

Foss has stated that the tugs are powerful enough to escort the largest tankers and container ships calling on ports on the West Coast. The class is certified ABS loadline A1 Towing Vessel A1 Escort Vessel AMS with a UWILD notation.