Designed by Seattle-based Elliott Bay Design Group and operated by Fire Island Ferries in Bay Shore, NY, Fire Island Maid is a unique 70-foot by 23-foot multi-purpose vehicle ferry currently running service from Bay Shore to a variety of Fire Island vacation communities. Fire Island Maid’s primary mission is to transport heavy equipment, such as cement trucks, garbage trucks, passenger vehicles and general cargo to and from the surrounding Fire Island communities, in addition to supporting dredging operations in the area.

Construction

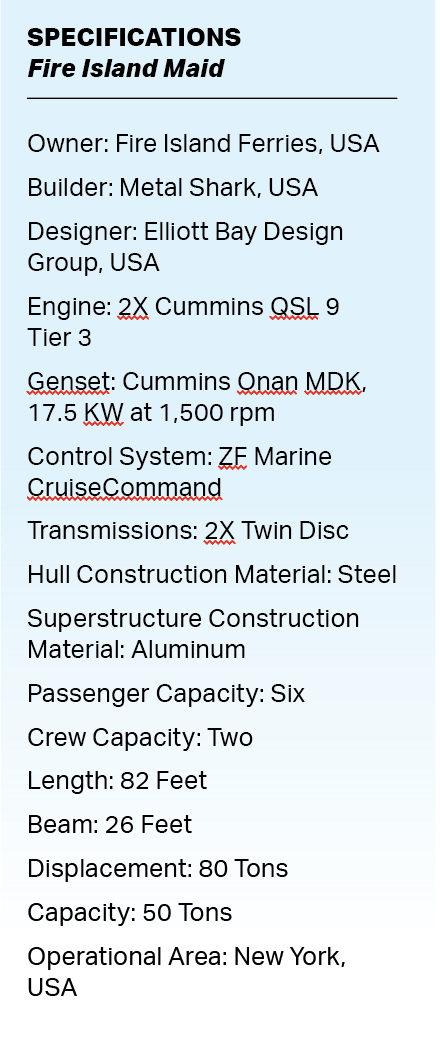

The ferry features a steel hull, aluminum superstructure, a hydraulically operated bow ramp for loading and unloading heavy equipment and a reinforced deck capable of supporting cargo up to 100,000 pounds. The vessel is powered by twin Cummins QSL9 Tier 3 marine engines with ZF Marine CruiseCommand control system and Twin Disc transmissions with a Cummins Onan MDK generator providing electric power.

The vessel has a lightship weight of just 160,000 pounds. The pilot house accommodates two crew and up to six passengers (assumed to be in their vehicles).

Metal Shark (formally Horizon Shipbuilding)—a leading builder of custom vessels for commercial and defense applications worldwide)—built Fire Island Maid at their Bayou La Batre, Ala. shipyard.

According to Fire Island Ferries, Metal Shark won the bid based on the company’s reputation for quality builds, price and its yard availability at the time. Elliott Bay’s design process began in July 2021 and Metal Shark completed the build early this year. The vessel was shipped to Bay Shore and officially entered service in March.

A More Versatile Turtle

Fire Island Ferries tasked Elliott Bay with replicating its existing workhorse, The Turtle, which transports heavy equipment to and from the island. However, the deadweight of The Turtle exceeds the lift capacity of Fire Island’s work yard hydraulic lift. Project manager Joseph Cardella said the challenge for them was to successfully design a ferry similar in mission, size and capability to The Turtle, yet light enough to meet the lift capacity of the existing infrastructure.

“The win for Elliott Bay is we took an existing vessel that’s in operation and we optimized that design. We listened to the client. We listened to their needs,” the company said in a statement. “We addressed their needs of what they wanted the vessel to do, mission specifically, and met specific parameters, such as the lifting capacity.”

To abide by the necessary weight parameters, Elliott Bay applied design modifications that shortened the vessel by roughly 10 feet and re-positioned the deckhouse to the starboard quarter. In addition, the design reduced the deckhouse’s height, as compared to The Turtle.

According to Fire Island Ferries’ General Manager and Director of Operations, Dave Anderson, The Turtle was overbuilt to the extent that their 85-ton bolt lift could not accommodate it. The new design of Fire Island Maid addressed this need.

“(Fire Island Maid) is purpose-built and designed for the communities we serve on Fire Island. With it being 10 feet shorter, the Maid is easier to navigate in tight spots, which are common in the area,” the company said. “And of course, it affords us the ability to haul the vessel with our 85-ton travel lift. Generally speaking, it’s a much more versatile boat for our needs, which was the project’s mission.”

Challenges

Challenges

According to both Cardella and Anderson, the biggest challenge in completing the project was location. With Fire Island Ferries based on Long Island, NY, the design group in Seattle and Metal Shark headquartered in the south, the completion of Fire Island Maid was a nationwide effort.

“The biggest challenge for us was location. With us being in Long Island and Metal Shark in Louisiana, it was very difficult to keep an eye on the project very closely like I normally do when a vessel is built at a nearby location,” Anderson said. “We’re definitely happy with the work Metal Shark did, and we’re proud of the result. Still, the scattered locations certainly added another challenging factor to the project.”

In addition to geographic locations, supply-chain issues presented additional hurdles.

“It’s a challenging environment to build boats these days,” Cardella said. “There are so many tiny electrical components to these boats, and when it takes forever to get each part, it can certainly delay the momentum of a project. With the location challenges, coupled with supply-chain issues, it can take quite a while for a vessel to be constructed, even a small boat like Fire Island Maid.”

Fire Island Maid took just under two years to complete, from concept to operation.

Looking Forward

The addition of Fire Island Maid to Fire Island Ferries’ fleet provides the operator functional redundancy alongside The Turtle and helps better serve their needs. As a result, the operator has no plans to build another vessel of its kind, as their current fleet is sufficient.

“(Fire Island Maid) is a better fit for the operation. Now they have two vessels that can perform a multitude of tasks and provide further service to their customers,” Cardella said. “But now they have added versatility with Fire Island Maid because of its size, as well as the capability of easily lifting it in and out of the water due to its weight.”